Without scuba gear, the fastest approach was simply to cut the anchors. I wanted to inspect those connectors anyway.

Our first day with boots on the ground, and we were quite keen to see what we had on the loggers that were deployed in back in August. A fresh batch of data is always a great way to motivate yourself for fieldwork. So Trish headed out to Rio Secreto to collect the 1st generation drip sensors, while I met up with Gabriel and Marco from CEA to see about retrieving the Beta flow sensors we put in Akumal bay back in August. As we waited for a boat to become available Gabriel showed me the fantastic records that they had kept, and the locations they had selected for the deployments of the other two flow meters. One had been placed in the shallower south side of bay on October 13th, and the third unit was deployed at the mouth of Yalku Lagoon on November 27th.

This pivot joint failure was discovered on Nov 7th, and the unit was re-installed on Nov 21st. (Photo courtesy: Centro Ecologico Akumal)

Opportunistic photos of the units every couple of weeks revealed that the constant roil of the surf had taken a toll: with both of loggers in the bay suffering failures on the anchor rods & pivot joints. I had designed the pearls for much gentler cave environments, so this was not unexpected. I was just thankful that the folks at CEA had been around to catch the problems while the “backup” bungee cords were still in place, or the loggers could have simply drifted away. Sometimes all you get from the first deployment is an understanding of how to do the next one better, and patchy data is still 100% better than no data at all. Of course, As I reviewed the photos with Gabriel, I could not help but wonder if the electronics had survived all that knocking about.

Gabriel had other pressing business that day, so when the boat became available Marco and I set off to retrieve the flow meters. At each site we did a quick check that the north orientation was still correct, and that there were no obvious signs of physical damage. It was a gorgeous day to be out, but the bright tropical sun made it impossible for me to determine if the leds were still piping. The first unit in the bay looked great but the second unit (in much shallower water) had suffered an incredible amount of bio-accumulation in only two months. I had never seen this on a sensor in the caves and it made wonder it if would even be possible to deploy ambient light sensors on a reef without some kind of rigorous cleaning schedule. By mid afternoon we had all the babies on board, and were heading back to shore.

The 0-ring seats were still clear. I guess PVC tastes better to sea critters than EPDM?

I spent a couple of hours scraping the gunk off of the housings with isopropyl alcohol before I dared to break a seal. And it was tough going, even with a pot scrubber. During the cleaning I could see that the LED on unit three was lit, indicating that it had gone into some kind of error state. Unit 4 piped on schedule, but I saw no flash from Unit 5. After the cleaning, it still took a wrench and some colorful language to loosen those bolts.

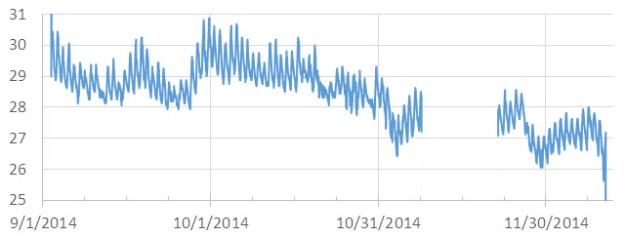

Once they were open I had a chance to look at the data files. All of them had saved at least 10,000 records, but unfortunately the data from Unit 3 consisted of the same four numbers, repeating over and over again. Inspection revealed that the SCL line on the I2C bus was broken. This had terminated the internal communications, although the RTC interrupt continued to fire on schedule for at least a month before it got confused and reset itself. So the logger from the south of the bay did not give us anything useful. Unit 4, the first to go in, was still running when I disconnected it and I was keen to how much power it had used in three months. (see: mV vs time in the graph below) These beta generation units were running some pretty hairy old code, and I knew they were probably pulling a few mA the whole time. I also had Unit4 on a five minute sample schedule, so it had saved almost twenty eight thousand records to the SD card:

No surprises there, with another 2-3 months of operation before this unit powered down. But it is worth noting how much spread there is in the voltage reading. This generation of loggers sported a TinyDuino stack so I used the AVR’s internal 1.1 vref to monitor the battery, and I was not expecting to see so much variability with the bandgap voltage method (>70 mV of noise?). When I use a voltage divider to read Vbat on my other builds, the readings are much more stable.

It will take me a while to chew the compass and accelerometer data into something useful but the temperature record really jumped out at me:

*repairing the anchor rod failure left a two week data gap in Nov.

For almost two months the night-time lows stay above 28 C, with some of the highs reaching 31 degrees. And this sensor (DS18B20) is not on the surface, but down in the middle of the water column at about 3m depth, pretty close to that reef. I’m no biologist, but it seems to be getting a little toasty down there…

Unit 5 was still running, although the LED ground line had been shaken loose, which I why I did not catch any pips. This build also had a 3.3v regulator one the power module, so I don’t have a battery voltage data to analyse. And finally, this unit did not go into the water till Nov 27th, so it’s flow data record is quite brief. However there was one other thing I could look at, before calling it a day: How much did those cheap eBay RTC’s I was using drift over the deployment? I found a lag of about 30 seconds in the RTC on Unit4, and about 40 seconds had been dropped from Unit5. I probably caused some of that delay myself as I was not setting the clocks very carefully back then, but it is still gives me some indication that these RTC boards should be good for a year long deployment. Not bad for a board that only cost two bucks.

Beta Unit 4 has now been under water for almost 10 months. The JB marine weld & Loctite epoxy are starting to show their age, in fact if the units were not under water the whole time, I’d say they were suffering from UV exposure. But I think they should still be water tight for a while, despite the fact that I exceeded any manufacturer specifications quite a while ago. The plan is to keep these early builds in service till the housings finally fail, but I would like to lower that sleep current before I deploy these units are redeployed. If memory serves, I never did get around to sleeping that bma250 in the Beta generation code (?)